Published on Nov 30, 2023

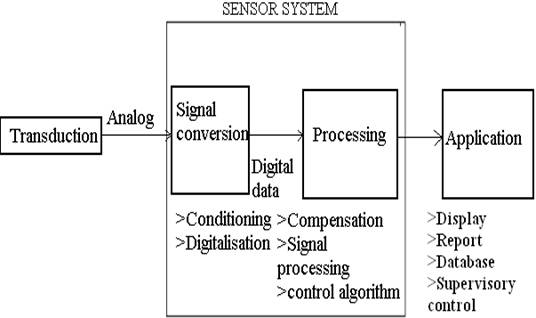

Most sensors put out some sort of analog signal a voltage, current, or resistance that varies in a fixed relationship to a physical parameter. Instrumentation that converts the signal to engineering units must know a few things about what parameters to expect from the sensor. That's because full-scale range, sensitivity, connection schemes, and other factors all vary greatly from one kind of sensor to another.

The end result is that it takes some effort to match up sensors with monitoring electronics. This configuration process may be no big deal when there are only a few sensors involved. But it can be problematic when gangs of sensors get wired into multichannel measurement systems.

A sensor is a device that measures a physical attribute or a physical event. It outputs a functional reading of that measurement as an electrical, optical or digital signal. That signal is data that can be transformed by other devices into information. The information can be used by either intelligent devices or monitoring individuals to make intelligent decisions and maintain or change a course of action.

A smart sensor is simply one that handles its own acquisition and conversion of data into a calibrated result in the units of the physical attribute being measured. For example, a traditional thermocouple simply provided an analog voltage output. The voltmeter was responsible for taking this voltage and transforming it into a meaningful temperature measurement through a set of fairly complex algorithms as well as an analog to digital acquisition. A smart sensor would do all that internally and simply provide a temperature number as data. Smart sensors do not make judgments on the data collected unless that data goes out of range for the sensor.

IEEE 1451.4 defines a relatively simple, straightforward mechanism for adding smart, plug and play capabilities to traditional analog sensors. Without adding any new hardware to the system, these plug and play sensors can bring real, immediate benefits in ease of use and productivity to any measurement and automation system that uses sensors. Additionally, IEEE 1451.4 defines a standard framework for sensor description, embodied specifically in the TEDS, which can scale from today's traditional analog sensors to tomorrow's smart networked sensors.

Two factors have promoted widespread adoption of plug-and-play sensors: the IEEE P1451.4 Smart Transducer Interface draft standard and the Internet. IEEE P1451.4 is a proposed standard for self-describing analog sensors using standardized Transducer Electronic Data Sheets (TEDS). The Internet can bring the plug-and-play concept to legacy sensors and systems via distribution of so-called virtual TEDS. The next generation of measurement and automation systems will use these concepts to become even more automated, robust, and smarter.

The 1451.4 standard calls for a mixed-mode interface. This is essentially the digital and analog signals being transferred back and forth between the signal conditioning hardware and the sensor, making it more compatible with the legacy sensors in place. The first three versions called for sending only digital data back to the computer. The next version of the standard being drafted now is P1451.5, which adds wireless capability to sensors. Right now, the P1451.4 is still a proposed standard which is expected to be ratified and issued by soon.

Plug-and-play sensors address the labor involved in connection and configuration. Based on open industry standards, plug-and-play sensors incorporate ways of automatically identifying themselves. Benefits include quicker, more automated system setup; better diagnostics; less downtime for sensor repair and replacement; and an easier time keeping track of sensors themselves as well as the data they generate.

The IEEE P1451.4 plug-and-play sensor concept appears to be one of those rare technologies whose strength and value come from its simplicity and focus. Although it doesn't fit many of the typical definitions of a smart sensor, it does provide real, tangible benefits in a way that builds on, not replaces, existing systems and technologies.

Because IEEE P1451.4 maintains the analog output of the sensor, the standard retains a high degree of compatibility with legacy sensors and instrumentation systems. The analog portion of these sensors and instruments are completely compatible with non-plug-and-play components, minimizing the investment risk of users and developers.

Also, the addition of the TEDS memory component to a sensor is a relatively simple engineering task, often requiring the addition of only a single 2-wire component that, in the case of a Class 2 sensor, doesn’t require any modification of the electrical interface circuitry of the sensor. In fact, the Class 2 interface can actually be implemented in a variety of ways, including placing the TEDS memory chip on the sensor, down the cable from the sensor, or even in the connector of the sensor. The add-on nature of Class 2 interfaces facilitates easy upgrade or retrofit of legacy sensors in the field to plug-and-play sensors.

As the technology for interoperable plug-and-play sensors becomes available, more users are experiencing the benefits of plug-and-play measurement and automation systems, including:

Quicker, more automated system setup

Improved diagnostics and troubleshooting

Reduced downtime for sensor repair and replacement

Improved sensor data management, bookkeeping, and inventory management

Automated use of calibration data

The most direct impact of plug-and-play sensors is quicker, more automated system setup. Without this technology, setting up and configuring a measurement system involves manually entering multiple sensor measurement parameters for each channel. For applications involving hundreds or thousands of sensors, this becomes a time-consuming and expensive process. Accurate entry of the data is critical because a data entry error or a sensor connected to the wrong input channel can lead to incorrect test data. Plug-and-play sensors eliminate the manual process, automatically uploading needed information into the measurement system and checking that each sensor is connected to the correct channel.

While these benefits are most obvious for large, sensor-intensive testing applications, the benefits of plug and play apply to any and all applications that involve an analog sensor-to-instrument interface. Whether it’s a simple digital meter readout or a networked, intelligent sensor node requiring more autonomous configuration and operation, IEEE P1451.4 provides simple, low-cost technology that simplifies sensor connectivity and use

| Are you interested in this topic.Then mail to us immediately to get the full report.

email :- contactv2@gmail.com |